Generators play a critical role in many industries by providing reliable power when needed most. Diesel generators are often a significant investment that businesses rely on for years.

Maximizing the life span of your diesel generator ensures that it can serve you for years. Proper preventative maintenance measures can help you extend your diesel generator’s life span while improving efficiency.

Multiple different factors influence the life span of diesel generators. Generally, a well-maintained generator can last anywhere up to 15 years. However, diesel generators that don’t get enough care or maintenance will last even shorter. While diesel generators can last longer than other generators, they require additional effort to ensure they can continue operating at maximum efficiency. Some of the critical factors that will play a role in the life span of your diesel generator include:

Every generator has specific needs based on the brand, age, sizing, environment and fuel quality. Your generator will need regular maintenance to stay operational for as long as possible. While diesel generators don’t have a specific number of hours they can operate for, you can get a general idea and the more maintenance and care you perform, the more you can extend the life span. A more efficient generator will last longer by reducing wear and tear on the different components, so taking the necessary steps to maximize your diesel generator’s efficiency is essential.

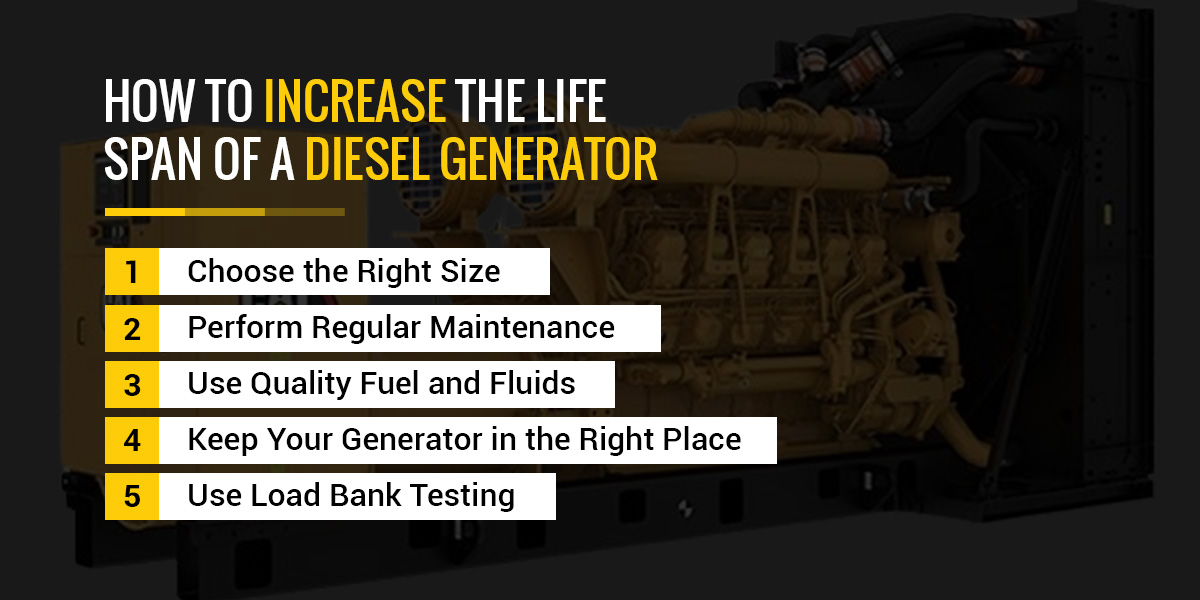

Learning how to care for and maintain your generator will extend its life span. Some of the best ways to extend the life span of your diesel generator include:

Diesel generators have specific load capacities. Choosing a generator that’s too small for your load size increases the wear and tear on the components and reduces the generator’s life span. It’s always a good idea to figure out your load size so you can choose the right generator capacity for your needs — this also means your generator is more likely to reach its maximum life span.

Maintenance is essential to maximize the performance of your diesel engine and extend its life span. A poorly maintained diesel generator will perform less efficiently and cause unnecessary strain on the different components. Maintenance should be performed every six months or 500 hours of operation, depending on which comes first. Maintenance should include:

Diesel generators perform at their best when you use high-quality fluids, such as coolant and oil. For example, low-quality fuels can cause build-up or clogging in the generator’s carburetor, resulting in costly repairs. A high fuel grade will help keep your diesel generator in the best condition possible, combating unwanted build-up and contaminants from damaging your system. High-quality fluids, such as oils and coolants, will help your generator perform at its best and extend its life span.

The location of your diesel generator will play a significant role in its life span since some locations aren’t suitable for diesel generators. Some locations to stay away from include:

Once you set up your generator, you should use an outdoor cover to ensure your generator is shielded from contaminants or substances that can cause damage, such as dirt, water, dust and debris. Protecting your generator will help prevent fuel degradation that can result in further problems and costly repairs. If your generator is installed inside, you must ensure that your venting system works properly and inspect it regularly to keep your work environment safe.

You can also work with portable diesel generators, which are a convenient way to move your generator across the work site or to different locations. However, you must follow the same rules with portable generators as a stationary model, keeping them away from windows, doors, air vents or flammable materials. Ensuring your generator is placed in the right location can help improve its efficiency and prevent any damage that could affect the overall life span of your unit.

Regular load bank testing can help you keep track of your diesel generator’s efficiency. Load bank testing should be performed alongside preventative maintenance to better understand the performance metrics of your diesel generator. Since most diesel generators aren’t used daily or regularly, load bank testing can help reassure that your system is operating effectively.

Load bank testing involves using an artificial load to bring the diesel generator to a specific operating temperature and internal pressure. The artificial load can determine whether the generator can run at the correct kilowatt output. Load bank testing also has additional benefits, including verifying electrical connections, removing carbon build-up and determining if any components may be failing. This testing can help you catch problems before they become significant and costly issues that affect the overall life span of your unit.

Diesel generator maintenance does more than extend the life span of your machinery. Routine maintenance also prevents issues, such as expensive repairs, lack of power and hazardous conditions. Regular maintenance has many benefits for your generator and business, including:

If you’re looking for a diesel generator or need generator service to maintain your system, Thompson Power Systems can help. We offer an extensive collection of new industrial generators and used power systems to help you find the right solution for your business. We also offer extended service coverage to help you properly maintain your equipment so you can maximize your investment.

We have served Alabama and Northwest Florida for over 60 years and can help you find an effective power solution to meet your needs. Find a location near you, or contact us today to get started.