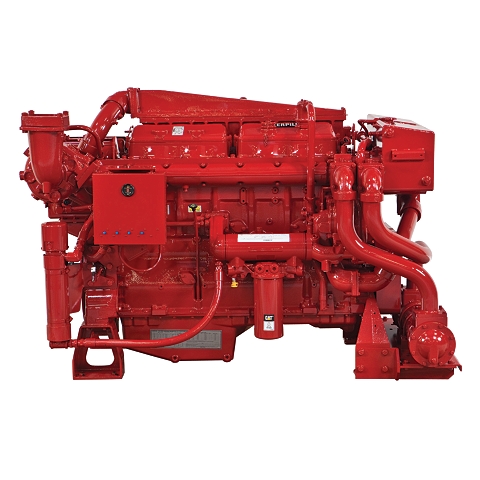

Product Description

The Cat® 3412C Industrial Diesel Fire Pump Engine is offered in ratings ranging from 476-551 kW (638-739 hp) @ 1750-2100 rpm. These ratings are non-certified and are available for global non-regulated areas. They are not FM Approved and not UL Listed. Starting on demand is a must for a fire pump engine – always. Cat® fire pump engines have a reputation for reliable starts and long efficient service.

Power Rating

- Maximum Power

- 739HP

- Rated Speed

- 1750-2100 rpm

- Minimum Power

- 638HP

Emission Standards

- Emissions

- Non-Certified. Available for global non-regulated areas. Not FM Approved, Not UL Listed

General

- Engine Configuration

- V-12, 4-Stroke-Cycle Diesel

- Bore

- 5.4in

- Stroke

- 6in

- Displacement

- 1648in³

- Compression Ratio

- 14.5:1

- Aspiration

- Turbocharged Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- -

Engine Dimensions - Approximate

- Length

- 78.7in

- Height

- 55.6in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 5686lb

Standard Equipment

-

- Air Inlet System

-

- Air cleaner, regular duty with service indicators

- Turbocharged

-

- Cooling System

-

- Thermostats and housing

- Jacket water pump, centrifugal

- Heat exchanger installed

- Expansion tank

-

- Control System

-

- Charging alternator 24 volt, 35 amp

- Governor control

- Hydra-mechanical governor

-

- Exhaust System

-

- Exhaust manifold

- Exhaust elbow, dry. 203 mm (8 in) on all Turbocharged engines and Turbocharged Aftercooled with wet exhaust. 152 mm (6 in) on Turbocharged Aftercooled with dry manifolds.

-

- Flywheels & Flywheel Housings

-

- SAE No. 0 flywheel

- SAE No. 0 flywheel housing

- SAE standard rotation

-

- Fuel System

-

- Fuel filter

- Fuel transfer pump

- Primary fuel filter

- Fuel priming pump

-

- Instrumentation

-

- Instrument panel, LH

- Engine oil pressure gauge

- Fuel pressure gauge

- Water temperature gauge

- Tachometer

-

- Lube System

-

- Crankcase breather, top mounted

- Oil cooler

- Oil filler in valve cover and dipstick, both RH

- Lube oil filter

- Rear sump oil pan

-

- Mounting System

-

- Supports

-

- Power Take Off

-

- Power take-off (PTO) flywheel stub shaft

-

- Protection System

-

- Stop-Start System, automatic (compatible with NFPA 20 requirements, able to be energized from either of two battery sources and capable of manual starter actuation)

-

- Starting System

-

- 24 volt, LH electric starting motor

- Jacket water heater (6 kW, 240-480 volt)

-

- General

-

- Paint: Firepump Red

- Vibration damper and guard

- Lifting eyes