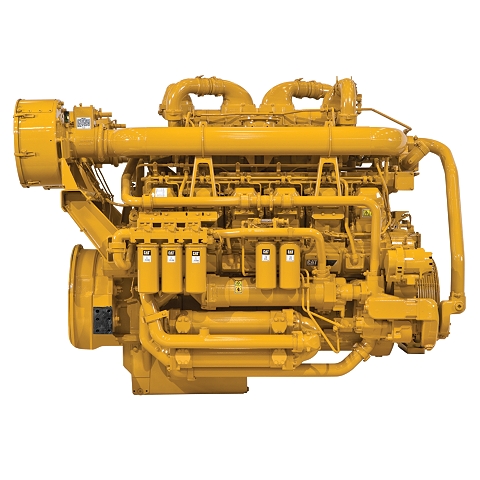

Product Description

For your largest power needs in any environment, Cat® 3512C Industrial Diesel Engines offer the unsurpassed performance and durability your customers need to keep their industrial applications and operations running. They deliver high power output, proven reliability and excellent fuel efficiency. These engines maintain low operating costs to keep your customers profitable for years to come. Industries and applications powered by 3512C engines include Bore/Drill Rigs, Chippers/Grinders, Construction, Cranes, Dredgers, Forestry, General Industrial, Material Handling, Mining, Mobile Earthmoving Equipment, Pumps, Shovels/Draglines, Surface Hauling Equipment and Trenchers. The 3512C engine, with a rating of 1120 bkW (1500 bhp) @ 1800 rpm, is U.S. EPA Tier 2 equivalent. It is available using U.S. EPA Flexibility, and for other regulated and non-regulated areas.

Power Rating

- Maximum Power

- 1500hp

- Maximum Torque

- 5259lb-ft @ 1500 rpm

- Rated Speed

- 1800 rpm

- Minimum Power

- 1500hp

Emission Standards

- Emissions

- U.S. EPA Tier 2 Equivalent

Engine Dimensions - Approximate

- Length

- 120.8in

- Width

- 70.3in

- Height

- 71.1in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 13400lb

General

- Engine Configuration

- V-12, 4-Stroke-Cycle Diesel

- Bore

- 6.7in

- Stroke

- 7.5in

- Displacement

- 3158in³

- Aspiration

- Turbocharged Aftercooled

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- -

Standard Equipment

-

- Air Inlet System

-

- Air to Air Aftercooled (ATAAC)

- Two turbochargers, rear mounted

-

- Control System

-

- Electronic Engine Control, RH

-

- Cooling System

-

- Thermostats and housing

- Gear driven centrifugal jacket water pump

- Connections for radiator cooling

-

- Exhaust System

-

- Exhaust manifold, dry

- Two turbochargers with watercooled bearings

- Two exhaust outlets, 203 mm (8 in) round flange

-

- Flywheels And Flywheel Housing

-

- SAE No. 00 flywheel (183 teeth)

- SAE No. 00 flywheel housing

-

- Fuel System

-

- Fuel filter, LH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

-

- Instrumentation

-

- No standard instrument or gauge panel

-

- Lube System

-

- Crankcase breather, top mounted

- Oil cooler

- Oil filler and dipstick, LH

- Oil pump

- Oil filter, LH, spin-on type

- Oil pan

-

- Mounting System

-

- Trunnion front support

-

- Power Take Off

-

- Front housing, two sided

-

- Protection System

-

- ECM monitoring system to provide customer programmable engine

- Deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40 pin customer interface connection

-

- Starting System

-

- Dual 24V electric starting motor

-

- General

-

- Vibration damper

- Lifting eyes

- Paint: Caterpillar yellow