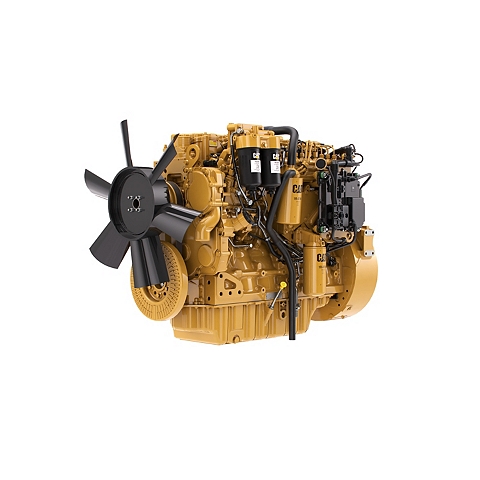

Product Description

Demanding conditions, applications and environments make the Cat?� C7.1 Industrial Diesel Engines in this power range the perfect solution for your severe duty equipment. With decades of diesel engine innovation and expertise behind these engines, they deliver the low operating costs and legendary Cat reliability and durability that give you a powerful advantage. More importantly, they’re backed by the world-class Cat dealer network ready to service and support every Cat industrial engine. Industries and applications powered by C7.1 engines include: Agriculture, Ag Tractors, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Combines/Harvesters, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Feller Bunchers, Forestry, Forklifts, General Industrial, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Sweepers, Paving Equipment, Pumps, Skidders, Specialty Ag Equipment, Sprayers, Trenchers and Underground Mining Equipment. C7.1 engines, with ratings: 116-205 bkW (140-275 bhp) @ 2200-2500 rpm, meet China Stage II, U.S. EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

Power Rating

- Maximum Power

- 275hp

- Maximum Torque

- 774lb-ft @ 1400 rpm

- Rated Speed

- 2200-2500 rpm

- Minimum Power

- 155.6hp

Emission Standards

- Emissions

- China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

Engine Dimensions - Approximate

- Length

- 36.6in

- Width

- 26.3in

- Height

- 32.2in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 1115lb

General

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Bore

- 4.1in

- Stroke

- 5.3in

- Displacement

- 427.7in³

- Aspiration

- Turbocharged Aftercooled (TA)

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- -

Standard Equipment

-

- Air Inlet

-

- Standard air cleaners

-

- Control System

-

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments, flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

-

- Cooling System

-

- Top tank temperature 108°C (226°F) as standard to minimize cooling pack size, 50:50 water glycol mix, detailed guidance on cooling system design and validation available to ensure machine reliability

-

- Exhaust System

-

- Diesel particulate filter and regeneration system supplied, with a range of inlet and outlet options

-

- Flywheels And Flywheel Housing

-

- Wide choice of drivetrain interfaces, including SAE1, SAE2 or SAE3 configurations

-

- Fuel System

-

- Electronic high pressure common rail, ACERTTM Technology, innovative filter design to ensure maximum protection of the engine.

-

- Lube System

-

- Wide choice of sumps for different applications

-

- Power Take Off

-

- SAE A or SAE B flanges on left-hand side. Right- hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications, factory fitted compressors are also available.

-

- General

-

- Paint: Caterpillar yellow, with optional colors available at request