Sustainable Electrical Power with Reciprocating Gen Sets

Reciprocating generator sets offer the opportunity to maximize existing renewable resources, and one of the ways utilities may invest in efficient and renewable power is through projects like power generation from landfill gas, biogas and coal mine methane (CMM) gas. The option to run generator sets on methane and methane-based fuels means that a generator set on a farm, near a landfill or at a coal mining site can run on readily available waste resources, while providing heat and power to buildings and offices near those locations. Implementing methods to use methane in reciprocating generator sets instead of emitting it to the atmosphere is energy efficient and cost efficient and could provide potential revenue.

Methane is released into the atmosphere through sources including landfill decomposition, agriculture and coal mining activities. Although methane occurs naturally in the atmosphere, it can be dangerous when released in large quantity. Emissions of methane have an estimated effect on global warming equal to 21 times the effect of carbon dioxide and, once released, methane remains in the atmosphere for approximately nine to 15 years. Landfill gas, biogas and coal mine methane are three of the most common and effective ways to run low energy-equipped reciprocating generator sets.

Landfill gas (LFG) is produced naturally as organic waste decomposes in landfills. LFG is composed of about 50 percent methane, about 50 percent carbon dioxide and a small amount of non-methane organic compounds. A landfill must be at least 40 feet deep and have at least one million tons of waste in place for landfill gas collection and power production to be technically feasible. LFG develops in landfills in approximately one to three years, depending on the type of waste and make-up of the nearby terrain; peak production of LFG is five to seven years after waste is dumped.

At most municipal solid waste landfills, the methane and carbon dioxide mixture is destroyed in a gas collection and control system or utility flare. However, to use LFG as an alternative fuel, the gas is extracted from landfills using a series of wells and a vacuum system. Pipes are inserted deep into the landfill to provide a point of release for the LFG. A slight vacuum is then applied in the pipe to draw the gases to a central point where they can be processed and treated for use in generating electricity, reducing the need for conventional fossil fuels.

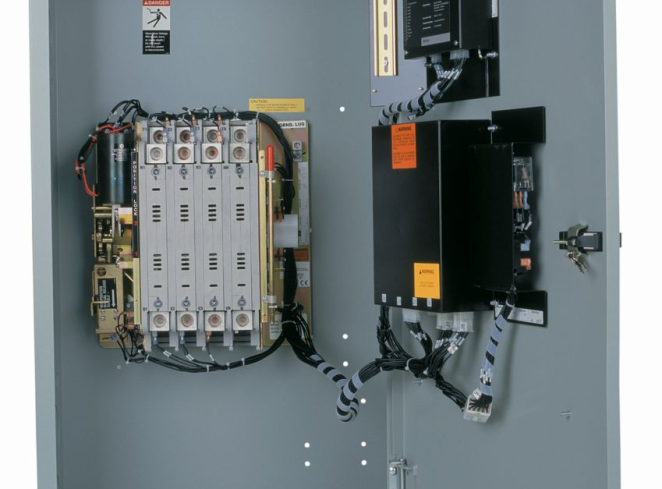

Guelph Hydro is a successful example of this landfill application. Guelph Hydro has taken advantage of LFG-to-energy since 2005. Utilizing three Cat G3516LE gas engines coupled to 925 kW, 600V SRB4 generators with Cat switchgear and PowerLynx™ controls, the generating plant runs continuously with each engine requiring about 340 cubic feet per minute (cfm) of gas to operate at maximum output. The G3516LE engines, operating at 1,200 rpm, are configured to be durable and reliable in burning low energy fuels without needing extensive fuel conditioning. The fuel treatment system at the Guelph landfill requires only a moisture removal system followed by a coalescing filter to remove remaining moisture droplets and particulates.

A specially designed cooling system elevates engine jacket water to the optimum temperature to prevent condensation of fuel-borne corrosive compounds. A crankcase ventilation pump ejects potentially acidic blow-by gases and draws in fresh, filtered air. In addition, aluminum and unprotected steel are eliminated from key components, such as aftercooler cores and main and connecting rod bearings.

The landfill has enough gas reserves to fuel the generators for about 20 years. Wells spaced 130 feet apart with an average depth of 50 to 65 feet capture methane from the landfill. Power from the plant goes to Guelph Hydro customers, equal to the needs of about 2,500 homes, meeting about one percent of the demand on its system. By turning the LFG to create electricity, the project has reduced pollutant emissions by about 100,000 tons.

Similar to LFG, biogas is produced through the natural anaerobic decomposition or fermentation of organic waste, such as manure, municipal solid waste, biodegradable waste or any other biodegradable feedstock within an anaerobic environment. Biogas consists primarily of methane (50 to 80 percent) and carbon dioxide (20 to 50 percent), with trace levels of other gases such as hydrogen, carbon monoxide, nitrogen, oxygen and hydrogen sulfide.

Biogas can be extracted for use with reciprocating generator sets from almost any of its sources. For example, some livestock farms or large livestock feeder operations use a lagoon to cover and store the manure generated by their livestock. Instead of releasing the methane and carbon dioxide generated by the decomposition of this manure into the atmosphere, the methane can be extracted and burned at the farm in biogas-fueled gas engines. Other agricultural operations, like starch-producing cassava processing plants, utilize anaerobic biodigesters to convert organic-rich wastewater into methane. By tapping their biogas resources, these farms and plants supplement their own power generation capabilities and lower their costs of purchasing heavy fuel oil and electricity.

Methane Gas Generators Utilizing Coal Mine Methane

Coal mine methane is another option for using cleaner fuel in reciprocating generator sets. At coal mining sites, gas drainage systems can be used to extract the methane-rich gas that exists in coal beds. Similar to the method used in landfills, vertical or horizontal wells are drilled into the coal bed and vacuum pressure extracts the methane. This type of extraction can yield very high quality gas, often with a methane content above 85 percent being common, especially from wells drilled into the coal seam well ahead of the actual mining. Wells drilled into the face of the coal seam as it is being mined typically have more air mixed with the methane gas as it is gathered; this gas is generally composed of 25 to 60 percent methane.

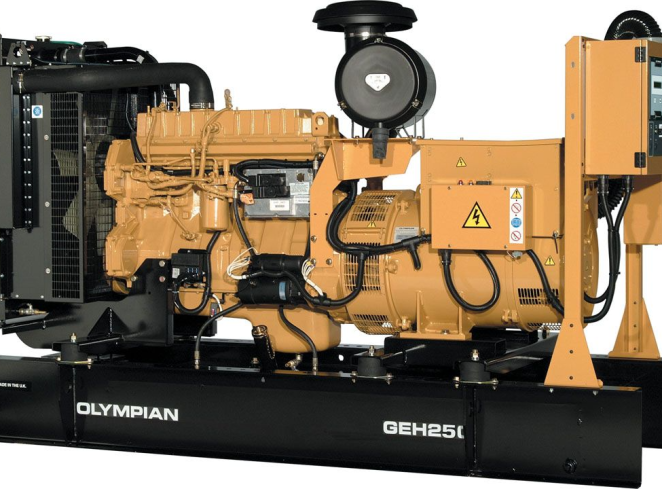

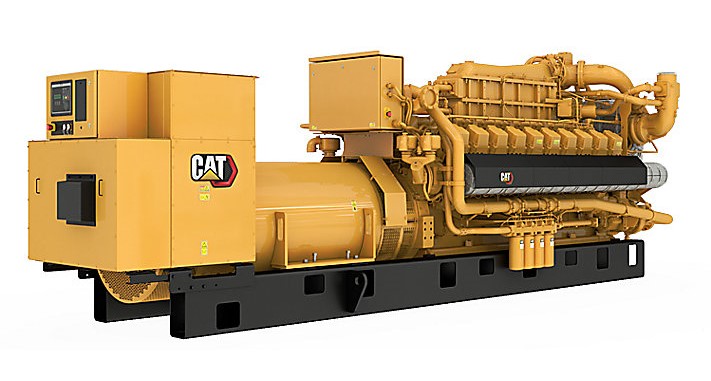

Maxim Power Corporation found that by installing a Cat G3520C generator set alongside three existing cogeneration units at a power plant on Vancouver Island, they were able to increase the amount of power they supply to the local utility by 1.6 MW. The engine’s power density rating of 80 kW per cylinder and relatively low operating cost per kW (better than other engines in this application) augment its capability of utilizing low BTU methane gas as fuel. Running at 1,200 rpm, the G3520C, produces 2,144 horsepower and supplies 600 volts. Its switchgear and step-up transformer convert this to 25,000 volts for sale to BC Hydro.

Working in tandem with the cogeneration units, the G3520C helps the plant recover 6.7 MW of heat from exhaust, water jacket, intercoolers and oil exchangers to provide 194°F water for a local greenhouse’s boiler. The generator sets use close to 100 percent of the methane from the landfill and capture more than 85 percent of the total available energy in power and heat. No flaring is necessary.

To meet the needs of customers seeking to use biogas as fuel, Thompson Power Systems offers the G3520C low-energy fuel generator set for use with methane fuels found in landfills, coal mines and other low-energy biogas environments. The new generator set includes equipment that optimizes the performance of engines in parallel-to-grid, continuous-operation applications. This generator set was specially designed to handle fuel with methane concentration variations that are typical of landfill, biogas and CMM operations. The G3520C package is also designed to efficiently and reliably use fuel gas with lower than-typical methane content. Special approval and engine configurations can be arranged for applications with methane content as low as 25 percent.

Protections like special “hardened” features are also available on the G3520C generator set to offer security against the corrosive nature of biogas and LFG in situations where minimal fuel pretreatment is desirable. For example, the landfill-specific design minimizes the use of bright metals such as copper and unprotected steel in components likely to come in contact with the fuel or exhaust gases, which are naturally acidic. The aftercooler cores, made of copper alloys in standard gas engines, are made of stainless steel in Cat landfill generator sets to resist attack from the acids in sulfur, chlorine and fluorine.

Equipped with a gas engine control module using ADEM™ III electronic controls, the generator set allows for full engine control from a single source. It can utilize fuel from a range of 25 to 100 percent methane, so the equipment remains efficient throughout the life of a landfill or coal mining project.

The Cat G3520C is available in both 50 and 60Hz models and can be used in LFG, biogas and CMM applications.

Reciprocating generator sets are fuel flexible, making them a cornerstone of one possible strategy for reducing our country’s dependence on foreign oil and non-renewable energy resources.

LFG and biogas may both be used to power fuel-flexible reciprocating generator sets, but low nitrogen oxide-producing natural gas may also be used. The efficiency of the generator sets is proven, with their ability to capture and reuse waste heat for CHP applications, while meeting national and local standards for emissions. When utilities are encouraged through decoupling to take advantage of the benefits of renewable fuels and CHP systems, those benefits can be managed from a central source and distributed locally to consumers, allowing communities to be involved with the process of creating and conserving the energy they use.

Biogas Gensets

Biogas is a sustainable, economical, and efficient alternative to fuels like diesel and natural gas. Cat® gas gensets have been designed to help you maximize the long-range cost savings and environmental benefits from biogas.

Using biogas from organic waste to power Cat® biogas generators, you can:

Reduce greenhouse gas (GHG) emissions;

Generate revenue sharing gas and energy with the grid network;

Reclaim valuable land normally used for wastewater purification; and

Eliminate odor and pest issues.

Cat biogas generators are specifically engineered to withstand the rigors of biogas applications. Key components are hardened against the corrosive properties of the gas, maximizing longevity and efficient operation. Your Cat generator handles variations in methane content with ease, while optimizing efficient, effective conversion of the gas to electrical power. When a combined heat and power (CHP or cogeneration) system is added to the infrastructure, the efficiencies increase still further, generating electrical and thermal energy that can be used to provide space heat and/or hot water to your site.

Thompson Power Systems will provide you with expert advice and support for your biogas generator set, offering expertise from specification and system architecture to commissioning and aftermarket support. With a tailored Customer Value Agreements for your service needs and intelligent remote monitoring technology, Thompson Power Systems will proactively protect your generator health by:

• Conducting preventive maintenance;

• Optimizing generator set solution performance and longevity; and

• Avoiding unplanned outages and costs.

See how we can produce electric power from landfill gas:

For more information on Biogas as a valuable renewable fuel, download this White Paper, “Biogas Comes of Age” for more information or fill out the Contact Us form below.