WHAT TYPE OF FUEL ISSUES COULD EXIST?

There are 3 ways deterioration could impact your fuel and ultimately your generator’s engine:

Environmental Deterioration – occurs when there are large changes in temperature, microbial contamination and exposure to heat and pressure from the engine’s injection system;

Production Deterioration – occurs due to the time fuel has been in transport or storage and the breakdown of that fuel as a result of natural oxidation, of the influence of production additives to the fuel and of biofuels introduced as fuel additive; and

Fuel Movement Deterioration – occurs as fuel that is heated by engines and later emptied back into their day tanks tends to break down quicker causing condensation in the tank resulting in poor quality fuel.

Poor fuel quality is a leading cause of generator engine performance problems. With today’s increasingly complex engine and injection systems, the tolerances on your generator’s engine is even tighter. Even small amounts of contaminants can cause loss of power, incomplete combustion, excessive emissions and injector failure, all of which lead to increased operating costs and potential generator failure.

CAN FUEL DETERIORATION SHUT DOWN YOUR MACHINE COMPLETELY?

Yes as volatile compounds begin to evaporate, your fuel creates a gum-like deposit that can plug and clog fuel pathways. This, in turn, causes lack of power, stalls, leaks and more in your generator’s engine.

WHAT OTHER ISSUES AFFECT GENERATOR ENGINE FUEL?

Running out of fuel is not good for your generator’s engine. When an engine runs out of fuel, the pump begins to pull air, ruining the injectors and air into your entire fuel system making start-up difficult.

Avoiding water in your fuel tank is also important. When water is present in your tank, it can be introduced into the fuel system and internal engine components. Caterpillar components are built to exacting tolerances which require the lubricity in fuel to prevent wear and damage.

In addition, water contamination can cause the following systems: (1) difficult or hard starting; (2) hesitation and/or sputtering; (3) erratic and/or unstable generator output.

Not only does this cause harm to pistons, it also damages injectors if water is sitting long enough, it will rust out your fuel system.

IS FUEL TESTING THE SOLUTION?

By testing your fuel, you can learn what kind of contaminates are affecting your generator’s engine and work on ways to better your fuel conditions and quality.

Avoiding testing your fuel could leave you with catastrophic failure when you need your generator to run.

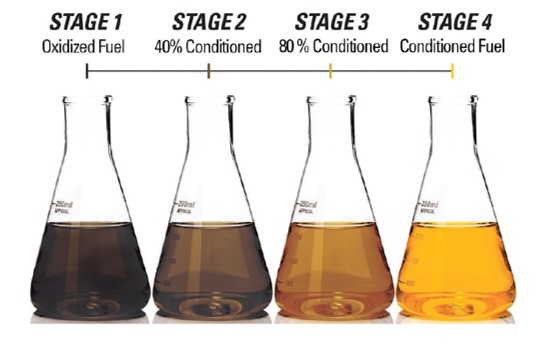

If testing your fuel reveals a problem, fuel conditioning may be the solution.