If your generators are not performing as well as they should be, a voltage drop might signify a problem. There are several causes of voltage drops — in most cases, repairing the generator is possible. Here, we discuss voltage drop formula calculations and how to diagnose voltage drops in generators.

A voltage drop refers to decreased electrical potential flowing from the circuit to the load. When a voltage drop occurs, there is insufficient power to support the load. If the voltage reading is too high, sensitive loads will endure damage.

It’s fairly easy to determine a voltage drop because the load will not receive sufficient power to run efficiently, and you’ll notice the effects. For example, in light bulbs, the bulb will dim or not light up at all. In generators, you may hear the motor struggling.

The easiest way to calculate voltage drop is with a multimeter. This device can measure multiple electrical properties. To collect the voltage reading, you must connect the multimeter’s copper conductors to either end of the cable that connects the generator to the load. While the device will provide the reading, you must perform some calculations to determine if the voltage reading is too high or too low.

The formula to calculate a voltage drop is:

While K is the resistance measured in Ohms of 1 circular mil, L refers to the length of the cable in feet, and I is the amperes. Cm is the cross-sectional area of the conductor in circular mils.

In a 300-foot-long cable bearing a load of 300 amps, the calculation would be:

Generator voltage drop calculations follow the same formula. A diesel generator voltage drop is standard when starting the motor and connecting equipment. However, the engine should recover within about one to four seconds. If the voltage reading does not reset, the generator could have a problem. A greater voltage drop also signifies that there may be a problem with the engine.

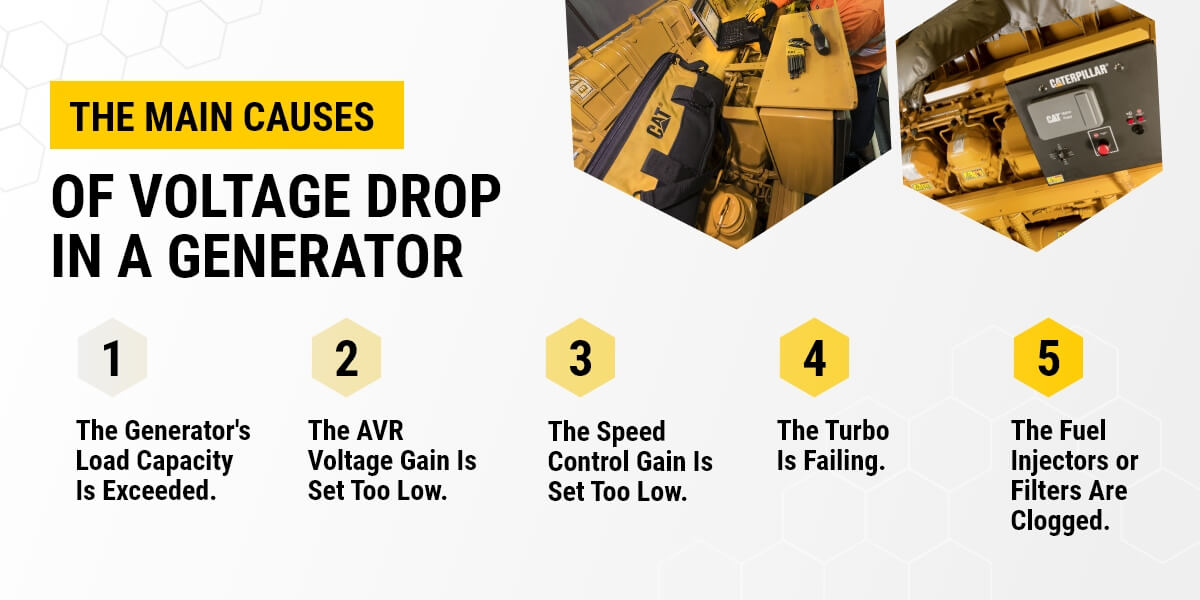

Voltage drops can damage the engine if the problem is not diagnosed. However, there are many different causes of voltage drops in diesel generators.

Generators have specific load capacities — they can only produce so much power. When the load connected to the generator exceeds its capacity, the voltage will drop as the machine slows down. When this happens, black exhaust will start leaking out.

Excessive loads can cause the generator to use more fuel and damage the engine and other internal components like cylinders and pistons. In extreme overloading cases, the generator’s engine can seize.

When straining capacity causes a voltage drop, disconnecting the device should allow the generator to restore its output rating. To avoid overloading in the future, follow the output rating on the generator. Never connect equipment and devices that exceed the output rating — calculate the joint load when using a generator to power more than one device.

The automatic voltage regulator (AVR) is the component in generators responsible for regulating voltage. This part can convert fluctuating voltage levels into constant ones. When the generator experiences an overload, the AVR automatically adapts the engine to the higher load. This part can also distribute loads that are operating in parallel or a voltage loop.

If the AVR voltage gain is set too low, it won’t be able to regulate load increases and changes, leading to a voltage drop. To adjust the voltage gain, you must remove the cover on the end of the generator. You’ll notice a kidney-shaped component on the left side — the AVR. You must remove a set of bolts without disconnecting the wiring. Then, turn the AVR over to locate a small box with a jeweler’s screw or the voltage adjustment screw.

Turn the screw counterclockwise to lower the voltage. The suitable voltage range is between 230V and 250V for generators of 5000V or more. The larger the capacity, the higher the AVR voltage gain setting should be.

The speed-regulating system of diesel generators is adjustable. When the engine’s flywheel rotates, the speed-measuring head on the shell generates a pulse voltage signal sent to the electronic speed governing board. When the speed is lower than the preset value of the regulating board, the voltage output from the speed regulator to the actuator increases along with the pump’s oil supply, causing the engine to reach its preset value.

The engine won’t respond to the load if the speed control gain is set too low. To adjust the gain setting, locate the speed governing board and adjust the gain potentiometer. Turn it clockwise until the generator vibrates and then counterclockwise until the vibration stops. Then, continue turning clockwise for a 1/8 turn.

A failing turbo will cause the engine to slow down. If this component cannot provide enough air pressure, the voltage reading will drop. If the load application is large, the engine could stall. In this case, you will notice black exhaust and poor or incomplete fuel combustion.

Even though a diesel generator can run without an efficient turbocharger, it won’t perform well. If the turbo is failing, a skilled mechanic can revive the part. However, a replacement part is sometimes necessary.

The fuel injectors and filters on a diesel engine can become clogged over time due to a buildup of hydrocarbons and sediment in the fuel. While most fuels contain ethanol to draw moisture into the fuel, the water in the fuel can be problematic for internal components and eventually cause rust.

General wear and tear over time can cause this issue. Using contaminated or dirty fuel is also a quick way to clog these components. Any kind of clog will cause a voltage drop, as the engine won’t be able to combust fuel efficiently.

If a clogged fuel injection or filters are the cause, you can add an injector cleaner to the fuel tank to clean the fuel injection. Be sure to use an injector cleaning product that is suitable for your generator’s make and model. Changing the filters on a generator is slightly more complex. It’s recommended to have a professional mechanic service the generator and replace the filters.

It’s often possible to repair generators that experience voltage drops. If reducing the load doesn’t solve the problem, contact us at Thompson Power Systems for reliable service options.

Our team can diagnose your generator’s issue and take steps to restore it. If the generator has a fault that can’t be repaired, we have a range of high-quality Cat® generators you can choose from so you can invest in a suitable replacement.

We serve customers in northwest Florida and Alabama, offering effective power solutions for over six decades. Contact us to learn more and find a location near you to get started with generator services.