If your business encounters damaged electrical equipment from a leak, flood, or mishap, knowing how to mitigate risks is essential for maintaining a secure environment. Water can cause electrical fires, electrical shorts, and electrocution, posing serious hazards to your facility and people. Explore the telltale signs of water damage and helpful tips for dealing with compromised components to promote safety in this guide for commercial businesses.

Below are key indications of electrical component water damage:

Understanding these signs will help your team act and resolve potential issues promptly. Early intervention is important for:

Carefully handling water-damaged electrical components is crucial to reducing safety risks and supporting optimal performance.

Educate your team on best practices when encountering water-damaged electrical equipment. Use the following steps as a guide.

Safety should always be the priority when dealing with potentially water-damaged equipment. Water and electricity are a dangerous combination. Electric shock accounts for around 1,000 fatalities and 30,000 nonfatal injuries every year in the United States — and its risks increase when exposed to moisture.

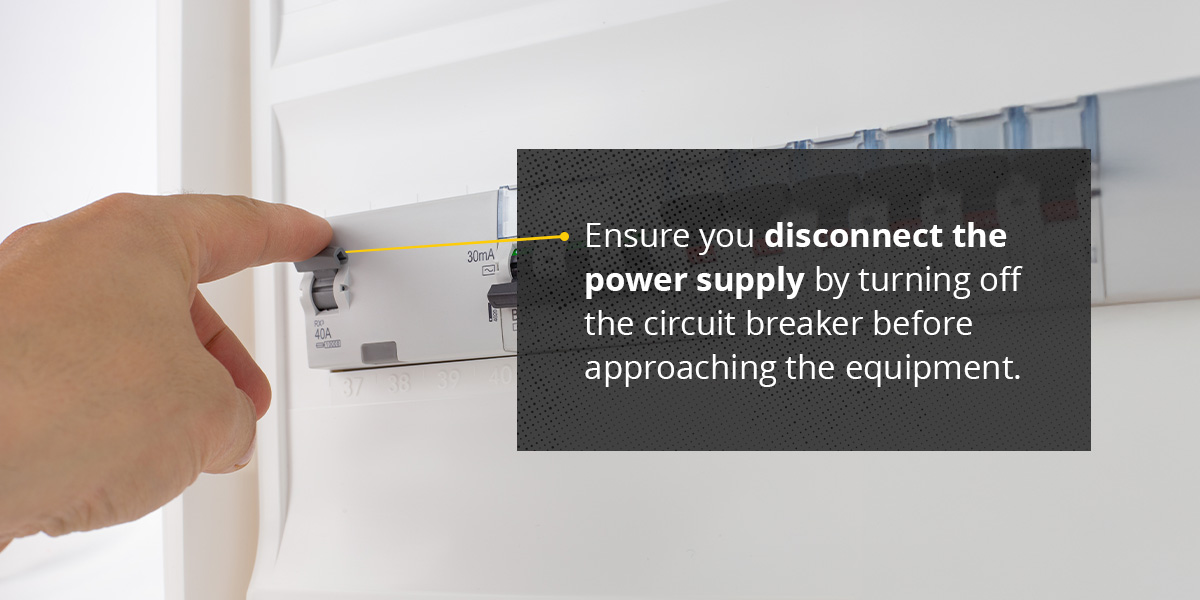

Ensure you disconnect the power supply by turning off the circuit breaker before approaching the equipment. Don’t attempt to unplug the device until you’re sure the power is off. Only qualified personnel should handle electrical equipment that may have water damage. They must wear proper personal protective equipment, such as gloves, eye protection, and rubber-soled shoes.

Assess the ground for any potential hazards like pooling water or damage that could pose additional threats. If you’re dealing with excessive water accumulation and are unsure whether or not your team can access the equipment safely, evacuate the zone and contact emergency services.

Always be cautious and put the safety of your personnel and facility first when handling potentially hazardous water damage.

Once your team ensures safety, they can visually inspect the suspected damaged electrical components. Examine the equipment’s exterior for signs of prolonged moisture exposure like discoloration or rust. Open all enclosures to assess their internal components, including wires, circuit boards, and connections. Areas where water has pooled are likely to have the greatest impact.

Consider documenting your findings by taking pictures and keeping detailed notes about the damage. You may be able to use these records to assess repair and replacement needs. They can also be highly beneficial if you’re making insurance claims.

If you notice significant damage, including melted wiring or burnt components, a professional’s assistance is necessary to ensure the safest removal process.

After your visual inspection, consulting a licensed electrician and certified equipment technician is best. They can help your team with the necessary tools and expertise to assess damage and guide the next steps.

A professional can also ensure your facility is compliant with local electrical codes and standards after an event resulting in water damage. Remember not to attempt to address any repairs to equipment without professional guidance. You could further damage the equipment or be unaware of additional safety hazards.

You can also work with a professional to establish preventive measures to avoid future water damage at your facility, helping ensure the longevity and reliability of your electrical equipment. Equipment experts can also determine when to repair parts versus replace damaged machines to support safety and cost-effectiveness.

If your equipment is unusable after water ruins a critical component, following proper disposal protocols is essential. Check your local regulations regarding electronic and equipment waste. Improper disposal can result in legal consequences and environmental hazards.

You may need to remove components, such as batteries, from the equipment and dispose of them separately. Document the disposal process for compliance purposes.

When dealing with water-damaged equipment at your commercial facility, you have two main options. You can either repair the affected components or replace the entire machine.

If your electrical equipment has minor surface damage or came in contact with minimal, clean water, you may be able to let it dry and repair its parts. If any internal components are ruined, there’s severe damage, or operating the equipment would lead to safety hazards, equipment replacement is necessary.

At Thompson Power Systems, we’re here to help your business get the power equipment and parts it needs to succeed. Our highly trained experts can help you develop a robust maintenance plan to keep your components in peak condition.

We’ve served clients in Alabama and Northwest Florida for over 65 years. Rely on us for unmatched customer service as your one-stop shop for new and used equipment sales, rentals, leasing, and parts.

Contact Thompson Power Systems to schedule maintenance or browse our power generation equipment today.